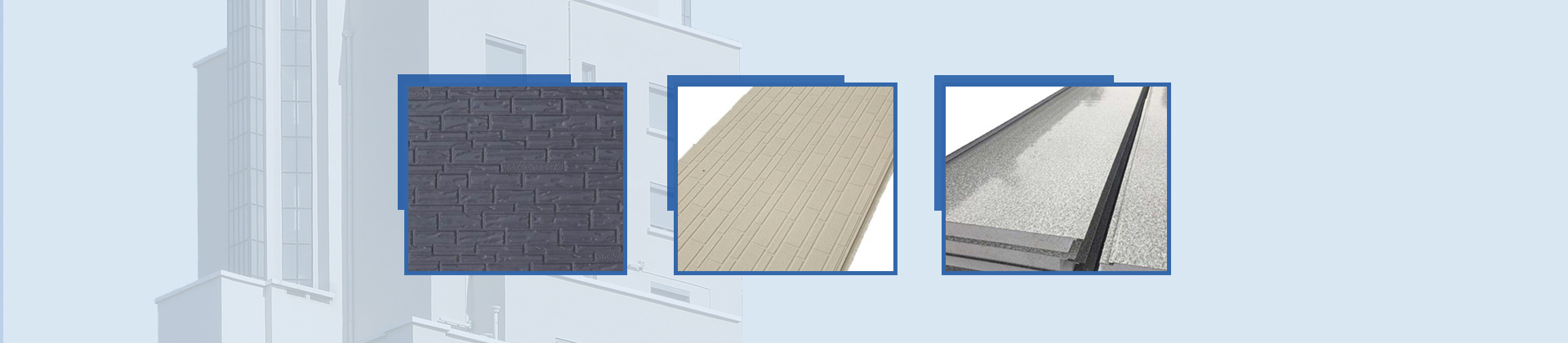

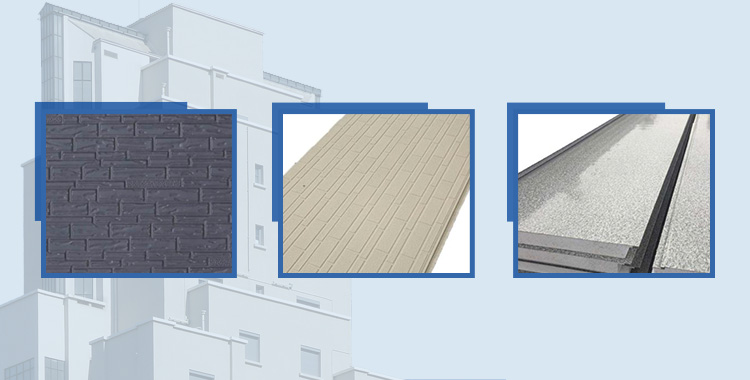

Embossed board manufacturers

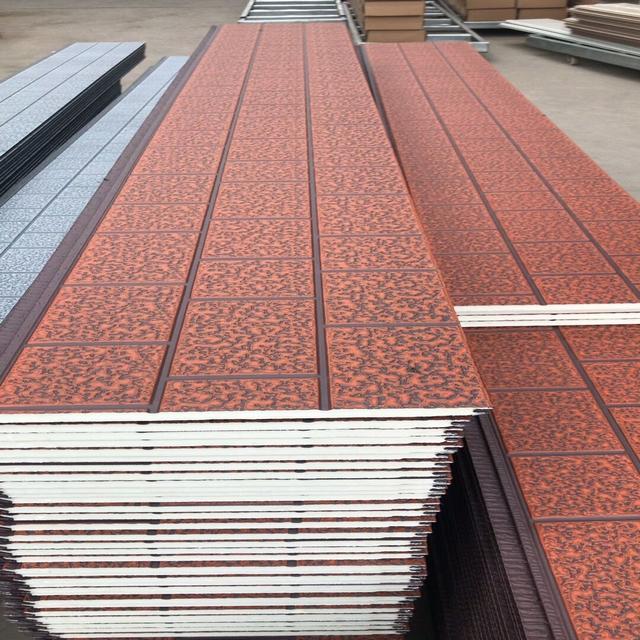

The metal exterior wall decorative board is composed of three parts, the upper surface is made of galvanized steel (aluminum alloy plate), and the surface is made of special high-weather-resistant paint. After a special coating process, the surface is painted with different colors according to the needs, and then the special metal embossing The equipment is rolled into different patterns and patterns, and after many times of painting, a variety of color embossed three-dimensional patterns are formed.It can meet the appearance requirements of architectural modeling and color, and achieve a certain artistic effect. The hard high-density environmentally-friendly polyurethane foam with flame-retardant treatment is used in the middle. Different regions can choose thermal insulation decorative panels with different foam thickness. The bottom has a protective layer of moisture-proof, heat-insulating, flame-retardant aluminum foil, glass fiber grade or steel plate according to different needs of customers.

1. Easy to install

It is light in weight and small in size. The weight per square meter is only 3.7 kg. It saves time and effort in transportation and installation, and is not restricted by seasonal climate and geographical environment. It not only speeds up the project progress, but also saves construction costs.

2. Waterproof and moisture-proof

The excellent self-structure and the compact concave-convex plug-in slot installation method between the plates avoid the structural damage caused by the rain, snow, freeze-thaw, dry-wet cycle, and eliminate water seepage and mildew.

Three, shock and crack resistance

The light weight, high strength, and good impact resistance not only reduce the weight of the building itself, but also greatly reduce the impact of the earthquake on the building.

Fourth, thermal insulation

Compared with traditional exterior wall thermal insulation decorative building materials, exterior wall panels have cold resistance and thermal insulation properties, which greatly reduces heating and cooling energy consumption.

Five, fire and flame retardant

After special treatment, it has good fire-retardant properties and is safe and worry-free.

Six, sound insulation and noise reduction

The middle core material is a heat-insulating and sound-insulating layer composed of high-density polyurethane foam, and its interior is an independent closed bubble structure, which has a good sound insulation effect.

It is widely used in the renovation of old buildings, sentry boxes, villas, mobile toilets, steel structure workshops, office buildings, etc.